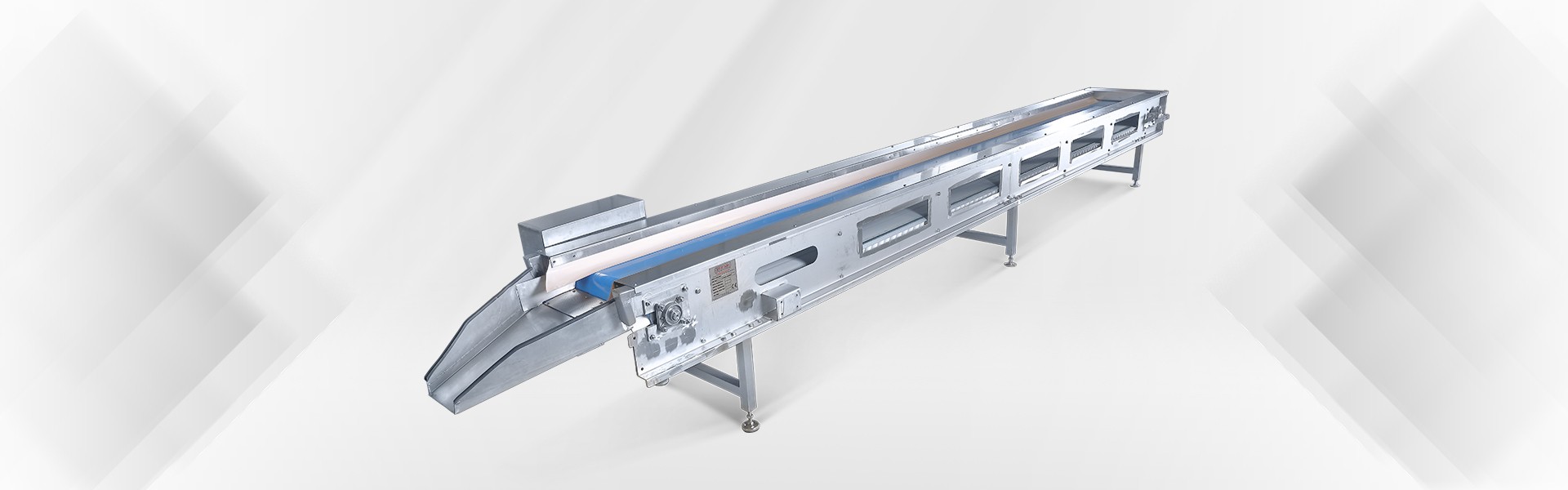

| Model Name | MAB-700 |

|---|

Machine interconnection belts are professional equipment designed to optimize production processes and provide reliable transport solutions for industrial needs. These belts can adapt to various production environments and operate seamlessly within a wide temperature range (-40°C to +70-80°C), demonstrating durability under challenging conditions across different sectors.

Manufactured with PVC, polyurethane, modular, rubber, wire belts, and stainless steel Schneider belt systems, these conveyors offer solutions tailored to all transportation needs. Additionally, elevator and conveyor options enhance the efficiency of transport processes, while belts designed in various sizes and configurations perfectly align with the installation area. This flexibility improves the performance of production facilities while ensuring energy efficiency.

Machine interconnection belts stand out for their hygienic and durable structures, making them ideal for both food and industrial production facilities. They reduce labor costs in production processes and ensure speed and reliability in transport operations. With stainless steel material options, these belts provide long-lasting use. Their modular designs allow for easy cleaning and maintenance, ensuring an uninterrupted production flow.

Machine interconnection belts feature customizable designs to support the transportation and production processes of various industries. Tailored to the specific needs of each facility, these systems are ideal for organizing production lines and optimizing processes. Conveyors increase operational efficiency through flexible transport capabilities. Especially in food processing plants, belts made from hygienic materials fully comply with food safety regulations.

With high-performance motors and durable structures, machine interconnection belts ensure reliability in production environments that require intensive use. Energy-efficient motor options and speed control features reduce operational costs while offering an environmentally friendly solution. Ergonomic designs help safeguard worker health, creating a safer working environment. Their long-lasting and modular structures provide easy installation and maintenance, making them an indispensable aid for increasing production capacity in industrial facilities.

Note: All materials in contact with food comply with TS EN 1672-2 Food Processing Machinery - Basic Concepts Part 2: Hygiene Rules Standards. All features are based on tomato processing data.